-

Table of Contents

“Master the Mechanics: Your Step-by-Step Guide to Installing a Hydraulic Motor in Heavy Machinery!”

Introduction

Installing a Hydraulic Motor in heavy machinery is a critical task that ensures optimal performance and efficiency in various applications. This step-by-step tutorial will guide you through the process, from gathering the necessary tools and materials to completing the installation safely and effectively. Understanding the specific requirements of your machinery and following proper procedures will help you achieve a successful installation, minimizing downtime and enhancing the overall functionality of your equipment. Whether you are a seasoned technician or a DIY enthusiast, this guide will provide you with the essential knowledge to tackle the installation with confidence.

Selecting the Right Hydraulic Motor for Your Heavy Machinery

Selecting the right Hydraulic Motor for your heavy machinery is a critical step that can significantly influence the performance and efficiency of your equipment. The process begins with a thorough understanding of the specific requirements of your machinery and the tasks it is designed to perform. To make an informed decision, it is essential to consider several key factors, including the type of application, the required torque and speed, and the operating environment.

First and foremost, it is vital to identify the type of application for which the Hydraulic Motor will be used. Different applications, such as lifting, pushing, or rotating, demand varying characteristics from a Hydraulic Motor. For instance, if the motor is intended for a lifting application, it will need to provide high torque at low speeds. Conversely, for applications that require rapid movement, a motor capable of higher speeds with lower torque may be more appropriate. Understanding the specific demands of your application will help narrow down the options available.

Once the application is defined, the next step is to determine the required torque and speed specifications. Torque is a measure of rotational force, while speed refers to the rate at which the motor can turn. These two parameters are often interrelated; thus, it is crucial to assess the load conditions and the desired performance outcomes. For example, if your machinery is expected to handle heavy loads, a motor with a higher torque rating will be necessary to ensure efficient operation. On the other hand, if speed is a priority, selecting a motor that can deliver the required revolutions per minute (RPM) without compromising torque is essential. Consulting the machinery’s specifications and performance requirements will provide valuable insights into the appropriate torque and speed ratings.

In addition to torque and speed, the operating environment plays a significant role in selecting a Hydraulic Motor. Factors such as temperature, humidity, and exposure to contaminants can affect the motor’s performance and longevity. For instance, if the motor will be used in a high-temperature environment, it is crucial to choose a model that can withstand such conditions without overheating. Similarly, if the machinery operates in a dusty or wet environment, selecting a motor with adequate sealing and protection against contaminants will enhance its durability and reliability. Therefore, evaluating the environmental conditions in which the Hydraulic Motor will function is essential for ensuring optimal performance.

Moreover, it is important to consider the compatibility of the Hydraulic Motor with the existing hydraulic system. This includes assessing the hydraulic fluid type, pressure ratings, and connection sizes. Ensuring that the motor is compatible with the hydraulic system will prevent potential issues during installation and operation. Additionally, consulting with manufacturers or suppliers can provide valuable insights into the best options available for your specific machinery.

Finally, budget considerations cannot be overlooked. While it may be tempting to opt for the least expensive option, investing in a high-quality Hydraulic Motor that meets all the necessary specifications will ultimately lead to better performance and lower maintenance costs in the long run. Therefore, balancing cost with quality and performance is crucial in making the right selection.

In conclusion, selecting the right Hydraulic Motor for heavy machinery involves a comprehensive evaluation of the application requirements, torque and speed specifications, operating environment, system compatibility, and budget constraints. By carefully considering these factors, you can ensure that your Hydraulic Motor will enhance the efficiency and effectiveness of your heavy machinery, ultimately leading to improved productivity and reduced downtime.

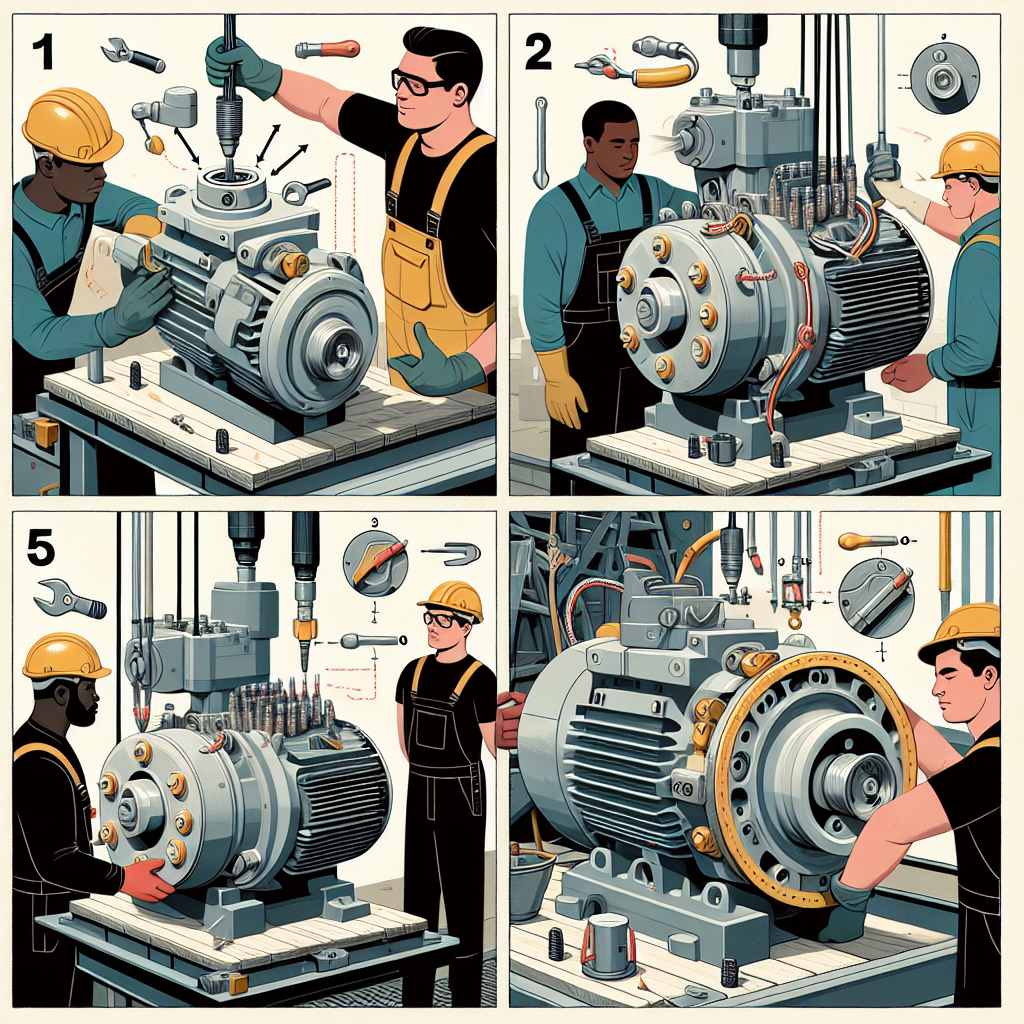

Step-by-Step Guide to Installing a Hydraulic Motor

Installing a Hydraulic Motor in heavy machinery is a task that requires precision, attention to detail, and a solid understanding of hydraulic systems. The process can be broken down into several key steps that, when followed carefully, will ensure a successful installation. To begin, it is essential to gather all necessary tools and materials before starting the installation. This includes the Hydraulic Motor itself, appropriate fittings, hoses, wrenches, and safety equipment such as gloves and goggles. Having everything on hand will streamline the process and minimize downtime.

Once the tools and materials are ready, the next step is to prepare the work area. This involves ensuring that the machinery is turned off and properly secured to prevent any accidental movement during the installation. It is advisable to consult the machinery’s manual for specific safety protocols and to identify the location where the Hydraulic Motor will be installed. After confirming that the area is safe, the next phase involves removing the old motor, if applicable. This typically requires disconnecting the hydraulic lines and electrical connections, followed by unbolting the motor from its mounting position. Care should be taken to capture any residual hydraulic fluid in a container to avoid spills.

With the old motor removed, the next step is to inspect the mounting surface for any signs of wear or damage. Cleaning the surface thoroughly is crucial, as any debris or old sealant can interfere with the proper installation of the new motor. Once the surface is clean, it is time to position the new Hydraulic Motor. Aligning the motor with the mounting holes is essential for a secure fit. It is advisable to use a helper during this stage to ensure that the motor is held steady while it is being bolted into place.

After securing the motor, the next step involves reconnecting the hydraulic lines. It is important to use the correct fittings and ensure that all connections are tight to prevent leaks. When connecting the hydraulic hoses, it is beneficial to refer to the hydraulic schematic provided in the machinery’s manual, as this will guide you in making the correct connections. Following this, the electrical connections should be re-established, ensuring that all wiring is intact and properly insulated.

Once all connections are made, it is crucial to check for any potential leaks before starting the machinery. This can be done by slowly pressurizing the system and observing the connections for any signs of hydraulic fluid escaping. If leaks are detected, it is imperative to address them immediately by tightening connections or replacing faulty components. After confirming that there are no leaks, the next step is to fill the hydraulic system with the appropriate fluid, as specified in the machinery’s manual.

Finally, after ensuring that everything is in order, the machinery can be started. It is advisable to run the machine at low speed initially, allowing the hydraulic system to circulate fluid and purge any air that may have entered during the installation process. Observing the motor during this initial run is essential to ensure that it operates smoothly and without any unusual noises or vibrations. If everything appears to be functioning correctly, the installation can be considered complete. By following these steps meticulously, one can successfully install a Hydraulic Motor in heavy machinery, ensuring optimal performance and longevity of the equipment.

Common Mistakes to Avoid When Installing a Hydraulic Motor

Installing a Hydraulic Motor in heavy machinery is a task that requires precision and attention to detail. While the process may seem straightforward, there are several common mistakes that can lead to inefficiencies, equipment damage, or even safety hazards. By being aware of these pitfalls, you can ensure a successful installation and optimal performance of the hydraulic system.

One of the most frequent errors occurs during the selection of the Hydraulic Motor itself. It is crucial to choose a motor that is compatible with the specific requirements of your machinery. This includes considering factors such as the motor’s size, power output, and operational speed. Failing to match these specifications can result in inadequate performance or excessive wear and tear on both the motor and the machinery. Therefore, it is advisable to consult the manufacturer’s guidelines or seek expert advice to ensure that the selected motor meets the necessary criteria.

Another common mistake is neglecting to thoroughly clean the installation area and the hydraulic components before beginning the installation process. Contaminants such as dirt, dust, and old hydraulic fluid can compromise the integrity of the hydraulic system. These impurities can lead to blockages, reduced efficiency, and even catastrophic failures. To avoid this, take the time to clean all surfaces and components meticulously. Additionally, using new seals and gaskets during installation can help prevent leaks and ensure a tight fit.

Moreover, improper alignment of the Hydraulic Motor can lead to significant issues down the line. Misalignment can cause excessive vibration, increased wear on bearings, and ultimately, premature failure of the motor. To prevent this, it is essential to use alignment tools and techniques to ensure that the motor is installed correctly. This may involve adjusting the mounting brackets or using shims to achieve the desired alignment. Taking these steps will not only enhance the performance of the motor but also extend its lifespan.

Furthermore, overlooking the importance of torque specifications is another mistake that can have serious consequences. Each component of the hydraulic system has specific torque requirements that must be adhered to during installation. Over-tightening can lead to stripped threads or damaged components, while under-tightening can result in loose connections and leaks. Therefore, it is vital to refer to the manufacturer’s specifications and use a calibrated torque wrench to ensure that all fasteners are tightened to the correct levels.

In addition to these technical considerations, it is also important to pay attention to the hydraulic fluid used in the system. Using the wrong type of hydraulic fluid can lead to poor performance and potential damage to the motor. Always refer to the manufacturer’s recommendations regarding fluid type and viscosity. Additionally, ensure that the fluid is clean and free from contaminants before filling the system.

Finally, neglecting to conduct a thorough testing phase after installation can lead to undetected issues that may arise during operation. It is essential to run the machinery at various speeds and loads to ensure that the Hydraulic Motor is functioning correctly. Monitoring for any unusual noises, vibrations, or leaks during this phase can help identify problems early on, allowing for timely adjustments or repairs.

By being mindful of these common mistakes, you can significantly improve the likelihood of a successful Hydraulic Motor installation. Taking the time to select the right components, maintain cleanliness, ensure proper alignment, adhere to torque specifications, use the correct hydraulic fluid, and conduct thorough testing will ultimately lead to enhanced performance and reliability of your heavy machinery.

Q&A

1. **Question:** What is the first step in installing a Hydraulic Motor in heavy machinery?

**Answer:** The first step is to ensure that the machinery is powered down and properly secured to prevent any accidental movement during the installation process.

2. **Question:** How do you connect the Hydraulic Motor to the hydraulic system?

**Answer:** Connect the Hydraulic Motor to the hydraulic system by attaching the inlet and outlet ports to the corresponding hydraulic lines, ensuring that all connections are tight and leak-free.

3. **Question:** What should be done after the Hydraulic Motor is installed?

**Answer:** After installation, check all connections for leaks, fill the hydraulic system with the appropriate fluid, and test the motor operation under low pressure before returning the machinery to full operation.

Conclusion

In conclusion, installing a Hydraulic Motor in heavy machinery involves careful planning and execution. Begin by gathering the necessary tools and safety equipment, then disconnect the power source and drain the hydraulic system. Remove the old motor, ensuring to document the connections for reference. Install the new Hydraulic Motor by aligning it properly, securing it with bolts, and reconnecting the hydraulic lines according to the manufacturer’s specifications. Finally, refill the hydraulic system, check for leaks, and test the motor’s operation to ensure everything functions correctly. Following these steps will help ensure a successful installation and optimal performance of the Hydraulic Motor.