-

Table of Contents

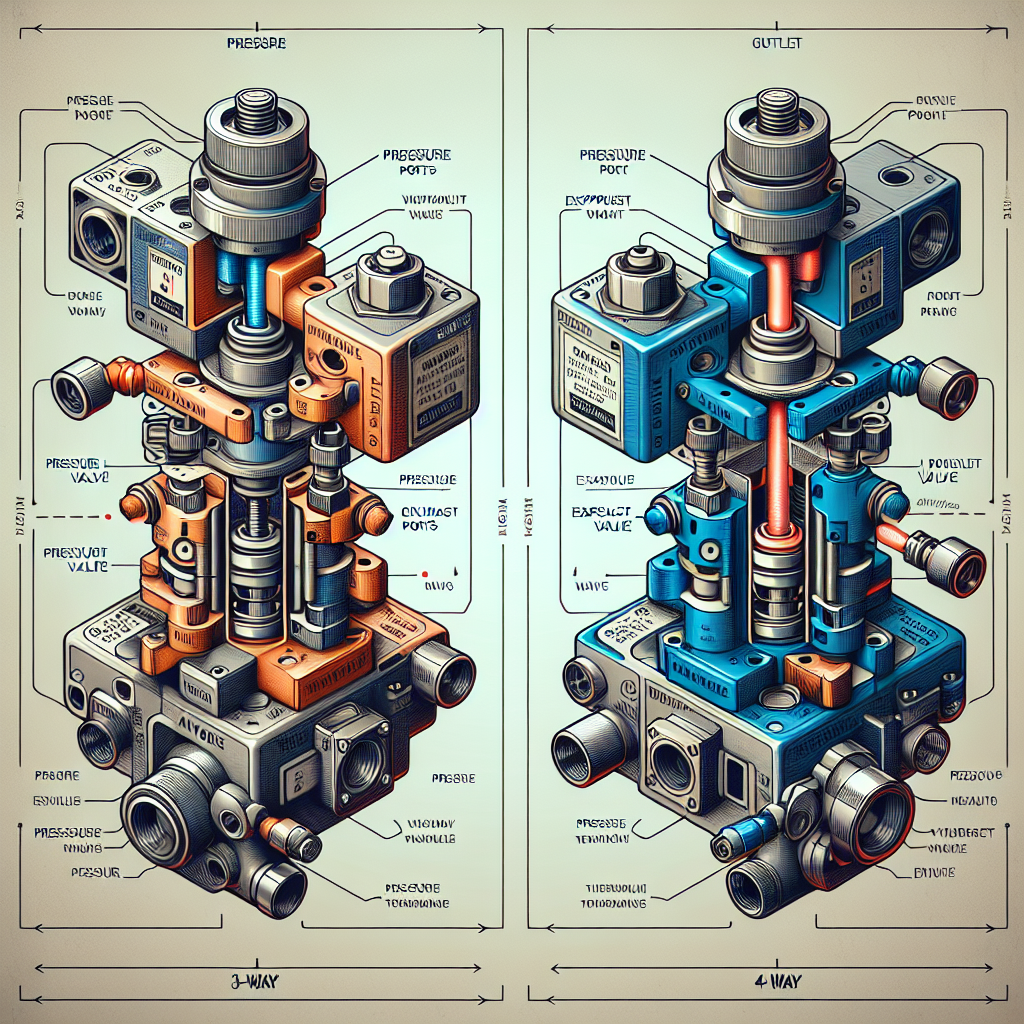

“3-Way vs 4-Way Solenoid Valves: Optimize Your Flow with the Right Configuration.”

Introduction

When it comes to fluid control in various industrial applications, selecting the appropriate Solenoid Valve configuration is crucial for optimal performance. 3-way and 4-way solenoid valves serve distinct purposes and offer unique advantages depending on the system requirements. A 3-way Solenoid Valve typically directs flow between two different paths, making it ideal for applications such as mixing or diverting fluids. In contrast, a 4-way Solenoid Valve can control the flow of air or fluid in multiple directions, often used in pneumatic systems to operate double-acting cylinders. Understanding the differences in functionality, installation, and application suitability between these two configurations is essential for engineers and technicians aiming to enhance system efficiency and reliability. This guide will explore the key features, benefits, and considerations for choosing between 3-way and 4-way solenoid valves.

Understanding Solenoid Valve Configurations: 3-Way vs 4-Way

When it comes to selecting the appropriate Solenoid Valve for a specific application, understanding the differences between 3-way and 4-way configurations is crucial. Both types of valves serve distinct purposes and are designed to control the flow of fluids in various systems, but their operational mechanisms and applications vary significantly. To make an informed decision, it is essential to delve into the characteristics and functionalities of each configuration.

A 3-way Solenoid Valve typically features three ports: one inlet and two outlets. This design allows for the diversion of fluid flow between two different paths, making it ideal for applications where the control of flow direction is necessary. For instance, in heating systems, a 3-way valve can regulate the flow of hot water to either a radiator or a hot water tank, depending on the demand. The simplicity of the 3-way configuration makes it a popular choice for straightforward applications where only two flow paths are required. Furthermore, these valves can be operated in either normally open or normally closed modes, providing flexibility in controlling the flow based on the system’s needs.

In contrast, a 4-way Solenoid Valve is equipped with four ports and is designed to control the flow of fluid in more complex systems. This configuration typically includes two inlet ports and two outlet ports, allowing for the simultaneous control of two different flow paths. A common application for 4-way valves is in pneumatic systems, where they are used to control the actuation of double-acting cylinders. By directing the flow of compressed air to either side of the cylinder, a 4-way valve enables precise control over the movement of the actuator, facilitating more intricate operations. The ability to manage multiple flow paths simultaneously makes 4-way valves indispensable in applications requiring coordinated movements or processes.

When considering which configuration to choose, it is essential to evaluate the specific requirements of the application. For simpler systems where only basic flow direction control is needed, a 3-way Solenoid Valve may suffice. However, in more complex scenarios where multiple flow paths must be managed, a 4-way valve is likely the better option. Additionally, factors such as the type of fluid being controlled, the pressure and temperature conditions, and the required response time should also be taken into account.

Moreover, the installation and maintenance aspects of each valve type should not be overlooked. 3-way valves are generally easier to install and maintain due to their simpler design, while 4-way valves may require more intricate setup and servicing. This complexity can lead to increased costs and longer downtime if maintenance is needed. Therefore, understanding the operational environment and the potential for future modifications is vital when making a selection.

Ultimately, the choice between a 3-way and a 4-way Solenoid Valve hinges on the specific needs of the application. By carefully assessing the flow requirements, system complexity, and maintenance considerations, one can make a well-informed decision that enhances the efficiency and reliability of the fluid control system. In conclusion, both configurations have their unique advantages and applications, and understanding these differences is key to optimizing performance in any fluid management scenario.

Key Applications for 3-Way and 4-Way Solenoid Valves

When it comes to selecting solenoid valves for various applications, understanding the key differences between 3-way and 4-way configurations is essential. Both types of valves serve distinct purposes and are utilized in a variety of industries, including manufacturing, HVAC, and automotive systems. The choice between a 3-way and a 4-way Solenoid Valve often hinges on the specific requirements of the application, including the flow direction, control needs, and the complexity of the system.

3-way solenoid valves are primarily designed to control the flow of fluids in a straightforward manner. They typically have three ports: one inlet and two outlets, or vice versa. This configuration allows for the diversion of flow from one outlet to another, making it ideal for applications where a single source needs to be directed to multiple destinations. For instance, in heating systems, a 3-way valve can effectively manage the flow of hot water to either a radiator or a floor heating system, depending on the demand. Additionally, these valves are commonly used in irrigation systems, where they can switch the flow of water between different zones, ensuring efficient water distribution.

On the other hand, 4-way solenoid valves are more complex and versatile, featuring four ports that allow for more intricate control of fluid flow. These valves are particularly useful in applications requiring the reversal of flow direction, such as in pneumatic systems where they control the actuation of double-acting cylinders. By directing air to one side of the cylinder while simultaneously exhausting the other side, 4-way valves facilitate precise control over the movement of machinery. This capability is crucial in automated manufacturing processes, where the synchronization of multiple actuators is necessary for efficient operation.

Moreover, 4-way solenoid valves are often employed in hydraulic systems, where they can manage the flow of hydraulic fluid to various components, ensuring that machinery operates smoothly and efficiently. In such applications, the ability to switch between different flow paths is vital for maintaining system performance and preventing potential damage due to improper fluid distribution. Consequently, industries that rely on hydraulic power, such as construction and automotive manufacturing, frequently utilize 4-way solenoid valves to enhance their operational capabilities.

In addition to their distinct functionalities, the choice between 3-way and 4-way solenoid valves can also be influenced by factors such as space constraints and installation requirements. For instance, in compact systems where space is at a premium, a 3-way valve may be preferred due to its simpler design and smaller footprint. Conversely, in larger systems where more complex control is necessary, a 4-way valve may be the better option despite its larger size.

Ultimately, the decision to use a 3-way or 4-way Solenoid Valve should be guided by a thorough understanding of the specific application requirements. By carefully considering factors such as flow direction, control complexity, and spatial constraints, engineers and system designers can select the most appropriate valve configuration. This thoughtful approach not only enhances system efficiency but also contributes to the longevity and reliability of the equipment involved. As industries continue to evolve and demand more sophisticated control solutions, the role of solenoid valves—both 3-way and 4-way—will remain pivotal in ensuring optimal performance across a wide range of applications.

Factors to Consider When Choosing Between 3-Way and 4-Way Solenoid Valves

When selecting between 3-way and 4-way solenoid valves, several critical factors must be considered to ensure optimal performance and efficiency in your specific application. Understanding the fundamental differences between these two configurations is essential, as each serves distinct purposes and operates under varying conditions.

To begin with, the primary function of a 3-way Solenoid Valve is to control the flow of fluid in a system by directing it to one of two outlets. This type of valve typically has three ports: an inlet and two outlets, allowing for either a mixing or diverting function. In contrast, a 4-way Solenoid Valve features four ports and is designed to control the flow of fluid in a more complex manner, often used in applications requiring the actuation of double-acting cylinders. The additional port in a 4-way valve allows for more versatile control, enabling the valve to alternate the flow direction and manage multiple functions simultaneously.

One of the first factors to consider is the specific application requirements. For instance, if the system involves simple on/off control or requires the redirection of flow between two paths, a 3-way valve may suffice. However, in applications where precise control of fluid direction is necessary, such as in pneumatic systems or hydraulic circuits, a 4-way valve is often the better choice. This distinction is crucial, as selecting the wrong valve type can lead to inefficiencies or even system failures.

Another important consideration is the complexity of the control system. A 4-way Solenoid Valve typically requires more intricate wiring and control logic due to its additional functions. Therefore, if the system design prioritizes simplicity and ease of maintenance, a 3-way valve may be more appropriate. Conversely, if the application demands advanced control capabilities, investing in a 4-way valve could provide significant long-term benefits, despite the initial complexity.

Furthermore, the flow rate and pressure requirements of the system should also influence the decision. 3-way valves generally have a higher flow capacity compared to 4-way valves of similar size, making them suitable for applications where high flow rates are essential. However, if the application involves lower flow rates but requires precise control over multiple actuators, a 4-way valve may be more advantageous. It is essential to evaluate the specifications of both valve types to ensure they align with the operational demands of the system.

Additionally, the medium being controlled plays a vital role in the selection process. Different fluids, whether they are gases or liquids, can affect the performance of solenoid valves. For example, if the application involves corrosive substances or high temperatures, it is crucial to choose a valve made from compatible materials. Both 3-way and 4-way valves are available in various materials, so understanding the medium’s properties will help in making an informed decision.

Lastly, cost considerations cannot be overlooked. While 3-way valves are generally less expensive than their 4-way counterparts, the long-term operational efficiency and maintenance costs should also be factored into the overall budget. In some cases, the initial investment in a 4-way valve may lead to greater savings over time due to reduced energy consumption and improved system performance.

In conclusion, choosing between 3-way and 4-way solenoid valves requires careful consideration of application requirements, system complexity, flow rates, the medium being controlled, and cost implications. By thoroughly evaluating these factors, one can make an informed decision that enhances the efficiency and reliability of the fluid control system.

Q&A

1. **What is the primary difference between 3-way and 4-way solenoid valves?**

A 3-way Solenoid Valve has three ports and can control the flow of fluid in one of two directions, while a 4-way Solenoid Valve has four ports and can control the flow in two different circuits, allowing for more complex operations such as reversing the direction of a cylinder.

2. **When should a 3-way Solenoid Valve be used instead of a 4-way Solenoid Valve?**

A 3-way Solenoid Valve is ideal for simple applications where only one flow path is needed, such as diverting flow between two outlets or controlling a single actuator, while a 4-way valve is better suited for applications requiring the control of double-acting cylinders or more complex flow patterns.

3. **What factors should be considered when choosing between a 3-way and a 4-way Solenoid Valve?**

Consider the application requirements, such as the need for flow direction control, the complexity of the system, the number of actuators involved, and the available space for installation, as well as the specific fluid dynamics and pressure ratings needed for optimal performance.

Conclusion

In conclusion, the choice between 3-way and 4-way solenoid valves depends on the specific application requirements. 3-way valves are ideal for diverting or mixing flows in simpler systems, while 4-way valves are better suited for applications requiring more complex control, such as reversing actuators or managing multiple flow paths. Consider factors such as system complexity, flow direction, and control needs when selecting the appropriate valve configuration to ensure optimal performance and efficiency.