-

Table of Contents

“Unlock Efficiency: Master Solenoid Valve Troubleshooting for Seamless Hydraulic Performance!”

Introduction

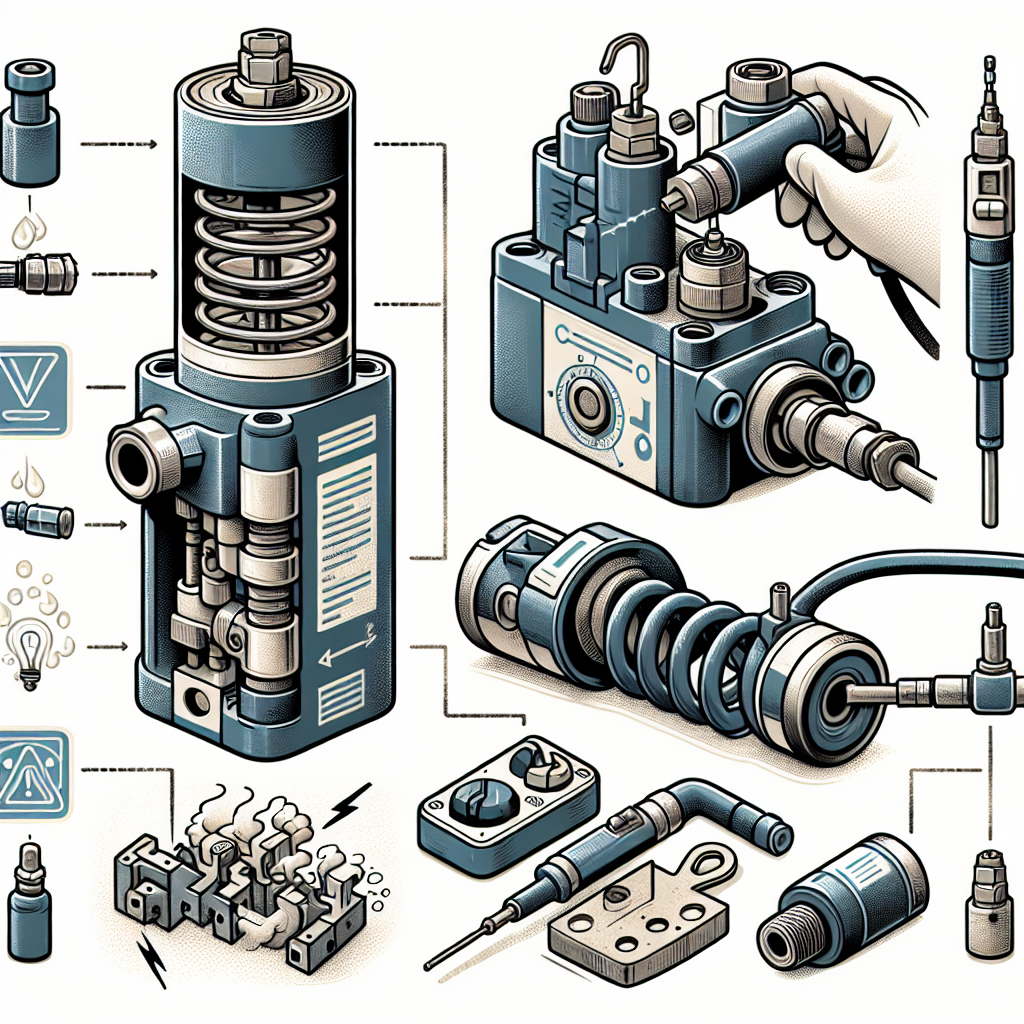

Solenoid valves play a crucial role in hydraulic systems by controlling the flow of fluids and ensuring efficient operation. However, like any mechanical component, they can encounter issues that disrupt system performance. Troubleshooting Solenoid Valve problems is essential for maintaining the reliability and efficiency of hydraulic systems. Common issues include electrical failures, fluid leaks, and improper valve operation, which can lead to system downtime and increased maintenance costs. This guide will explore effective strategies for diagnosing and fixing these common Solenoid Valve issues, helping technicians restore optimal functionality to hydraulic systems.

Common Solenoid Valve Failures and Their Symptoms

Solenoid valves are critical components in hydraulic systems, serving as electromechanical devices that control the flow of fluids. However, like any mechanical device, they can experience failures that may disrupt system performance. Understanding the common failures associated with solenoid valves and their symptoms is essential for effective troubleshooting and maintenance.

One prevalent issue is the failure to open or close properly. This malfunction can manifest in various ways, such as a complete lack of response when the solenoid is energized or de-energized. Often, this failure is attributed to electrical problems, such as a blown fuse or a faulty power supply. Additionally, a malfunctioning coil can prevent the solenoid from operating as intended. In some cases, the valve may be stuck due to debris or corrosion, which can impede its movement. Therefore, it is crucial to inspect the electrical connections and the physical condition of the valve to identify the root cause of the problem.

Another common failure is the Solenoid Valve leaking. This issue can occur at the valve body or the seals, leading to a loss of hydraulic fluid and reduced system efficiency. Leaks can often be traced back to wear and tear on the seals, which can degrade over time due to exposure to heat, pressure, or incompatible fluids. Additionally, improper installation or over-tightening of fittings can also contribute to leaks. When diagnosing this issue, it is important to check for visible signs of fluid accumulation around the valve and to assess the integrity of the seals and connections.

In some instances, solenoid valves may exhibit erratic operation, characterized by intermittent opening and closing. This behavior can be particularly frustrating, as it can lead to unpredictable system performance. Erratic operation is often caused by fluctuations in the electrical supply, such as voltage spikes or drops. Furthermore, electromagnetic interference from nearby equipment can disrupt the solenoid’s operation. To address this issue, it is advisable to examine the electrical supply and consider implementing protective measures, such as surge protectors or filters, to stabilize the voltage.

Another symptom that may indicate Solenoid Valve failure is unusual noise during operation. A properly functioning Solenoid Valve should operate quietly; however, if it produces clicking, buzzing, or grinding sounds, it may be a sign of internal damage or mechanical binding. Such noises can arise from debris lodged within the valve or from worn components that require replacement. Conducting a thorough inspection of the valve’s internal parts can help identify any issues that need to be addressed.

Lastly, solenoid valves may also experience overheating, which can lead to coil burnout and complete failure. Overheating can result from prolonged operation under high load conditions or insufficient cooling. It is essential to monitor the operating temperature of the solenoid and ensure that it remains within the manufacturer’s specified limits. If overheating is detected, it may be necessary to evaluate the system’s design and operational parameters to prevent recurrence.

In conclusion, recognizing the common failures and symptoms associated with solenoid valves is vital for maintaining the efficiency and reliability of hydraulic systems. By systematically diagnosing issues such as failure to open or close, leaks, erratic operation, unusual noise, and overheating, operators can implement timely interventions to restore functionality. Regular maintenance and vigilant monitoring can significantly reduce the likelihood of Solenoid Valve failures, ensuring optimal performance in hydraulic applications.

Step-by-Step Guide to Troubleshooting Solenoid Valves

Troubleshooting solenoid valves in hydraulic systems is a critical task that ensures the efficient operation of machinery and equipment. When issues arise, it is essential to approach the problem methodically to identify and rectify the underlying causes. The first step in troubleshooting begins with a thorough visual inspection of the Solenoid Valve and its surrounding components. Look for any signs of physical damage, such as cracks, corrosion, or loose connections. Additionally, check for any fluid leaks, as these can indicate a failure in seals or fittings that may affect the valve’s performance.

Once the visual inspection is complete, the next step involves verifying the electrical supply to the Solenoid Valve. It is crucial to ensure that the valve is receiving the correct voltage as specified by the manufacturer. Using a multimeter, measure the voltage at the solenoid terminals while the system is operational. If the voltage is absent or inconsistent, it may point to issues such as faulty wiring, a defective power supply, or a malfunctioning control circuit. Addressing these electrical issues is vital, as they can prevent the solenoid from actuating properly.

After confirming the electrical supply, the focus should shift to the solenoid’s operation. To do this, manually activate the solenoid by applying power directly to it. If the solenoid clicks or engages, it indicates that the coil is functioning correctly. However, if there is no response, the coil may be burnt out or damaged, necessitating replacement. Conversely, if the solenoid activates but fails to control the flow of hydraulic fluid, further investigation into the valve’s internal components is warranted.

Next, it is essential to examine the hydraulic fluid itself. Contaminated or degraded fluid can lead to Solenoid Valve malfunction. Check the fluid for signs of contamination, such as discoloration or the presence of particulates. If the fluid appears dirty, it may be necessary to change it and replace any filters in the system. Clean hydraulic fluid is crucial for the proper functioning of all components, including solenoid valves, as it ensures smooth operation and reduces wear.

In addition to fluid quality, the pressure within the hydraulic system should be assessed. Low pressure can prevent the Solenoid Valve from functioning correctly, while excessive pressure may cause damage. Use a pressure gauge to measure the system’s pressure and compare it to the specifications provided by the manufacturer. If the pressure is outside the recommended range, adjustments may be needed to restore proper operation.

Furthermore, it is important to consider the installation and orientation of the Solenoid Valve. Improper installation can lead to operational issues, including incorrect flow direction or inadequate sealing. Review the installation manual to ensure that the valve is positioned correctly and that all connections are secure. If necessary, re-install the valve according to the manufacturer’s guidelines.

Finally, if all previous steps have been completed and the Solenoid Valve still exhibits issues, it may be time to consult the manufacturer or a professional technician. They can provide additional insights or recommend specific repairs or replacements based on their expertise. By following this step-by-step guide, operators can systematically troubleshoot solenoid valves in hydraulic systems, ultimately leading to improved performance and reliability. Through careful inspection, testing, and maintenance, many common issues can be resolved, ensuring that hydraulic systems operate smoothly and efficiently.

Preventive Maintenance Tips for Solenoid Valves in Hydraulic Systems

Preventive maintenance is essential for ensuring the longevity and optimal performance of solenoid valves in hydraulic systems. By implementing a proactive approach, operators can significantly reduce the likelihood of unexpected failures and costly downtime. One of the first steps in preventive maintenance is to establish a regular inspection schedule. This schedule should include visual checks for signs of wear, corrosion, or leaks, as these indicators can signal underlying issues that may compromise the valve’s functionality. Regular inspections allow for early detection of potential problems, enabling timely interventions before they escalate into more significant failures.

In addition to visual inspections, it is crucial to monitor the electrical components associated with solenoid valves. This includes checking the wiring for frays or loose connections, as well as ensuring that the solenoid coil is functioning correctly. A malfunctioning coil can lead to erratic valve operation or complete failure, which can disrupt the entire hydraulic system. Therefore, testing the coil’s resistance with a multimeter can provide valuable insights into its condition. If the readings fall outside the manufacturer’s specifications, it may be necessary to replace the coil to maintain reliable operation.

Furthermore, maintaining the cleanliness of the hydraulic fluid is vital for the health of solenoid valves. Contaminants in the fluid can lead to blockages and wear on internal components, ultimately affecting the valve’s performance. To mitigate this risk, operators should implement a fluid filtration system and regularly change the hydraulic fluid according to the manufacturer’s recommendations. Additionally, monitoring fluid levels and ensuring that they remain within the specified range can help prevent cavitation and other issues that may arise from low fluid levels.

Another important aspect of preventive maintenance is lubrication. While solenoid valves typically do not require extensive lubrication, ensuring that moving parts are adequately lubricated can enhance their performance and extend their lifespan. Operators should refer to the manufacturer’s guidelines for specific lubrication requirements and intervals. Over-lubrication, however, should be avoided, as it can attract dirt and debris, leading to further complications.

Moreover, it is essential to keep an eye on the operating environment of the hydraulic system. Factors such as temperature fluctuations, humidity, and exposure to corrosive substances can significantly impact the performance of solenoid valves. Implementing protective measures, such as enclosures or shields, can help mitigate these environmental risks. Additionally, ensuring that the hydraulic system is not subjected to excessive vibration or shock can further enhance the reliability of solenoid valves.

Training personnel on the proper operation and maintenance of solenoid valves is another critical component of preventive maintenance. Well-informed operators are more likely to recognize early signs of trouble and take appropriate action before issues escalate. Regular training sessions can reinforce best practices and keep staff updated on any changes in maintenance protocols or technology.

In conclusion, preventive maintenance for solenoid valves in hydraulic systems encompasses a range of practices aimed at ensuring optimal performance and longevity. By conducting regular inspections, monitoring electrical components, maintaining fluid cleanliness, ensuring proper lubrication, protecting against environmental factors, and training personnel, operators can significantly reduce the risk of failures. Ultimately, a commitment to preventive maintenance not only enhances the reliability of solenoid valves but also contributes to the overall efficiency and productivity of hydraulic systems.

Q&A

1. **Question:** What are the common symptoms of a malfunctioning Solenoid Valve in a hydraulic system?

**Answer:** Common symptoms include erratic operation, failure to open or close, unusual noises, and fluid leaks around the valve.

2. **Question:** How can you determine if the solenoid coil is faulty?

**Answer:** Measure the resistance of the solenoid coil with a multimeter; if the resistance is outside the manufacturer’s specified range, the coil may be faulty.

3. **Question:** What steps should be taken if the Solenoid Valve is stuck in one position?

**Answer:** First, check for electrical issues, then inspect for debris or corrosion in the valve, and finally, apply manual force to free the valve if necessary, ensuring to follow safety protocols.

Conclusion

In conclusion, effective troubleshooting of solenoid valves in hydraulic systems is essential for maintaining optimal performance and preventing system failures. By systematically diagnosing common issues such as electrical faults, fluid contamination, and mechanical wear, technicians can identify and resolve problems efficiently. Regular maintenance, including cleaning and inspection, can also help mitigate potential issues before they escalate. Ultimately, a thorough understanding of Solenoid Valve operation and common failure modes is crucial for ensuring the reliability and longevity of hydraulic systems.